Introduction

A rotary encoder is an electromechanical device that attaches to a motor/shaft assembly in order to accurately report the position, speed and acceleration of the rotary shaft. It converts the angular position or rotational position of an object to analog or digital output signals.

They are widely used in automation, robotics, industrial machines, and other applications where precise motion control is required.

Types of Rotary Encoders

Encoders can be divided into two basic types: incremental and absolute encoders.

Depending upon the sensing technology rotary encoders are divided into categories like magnetic, optical, laser and capacitive.

- Incremental Rotary Encoder

- Absolute Rotary Encoder

- Magnetic Rotary Encoders

- Mechanical Rotary Encoders

- Optical Rotary Encoders

- Capacitive Rotary Encoders

Based on operating Principle

1. Incremental Rotary Encoder

Incremental rotary encoders, determine position information by calculating the changes in the rotating component of the assembly. They immediately report changes in position, which is an essential capability in some applications. However, it does not report or keep track of the device’s absolute position.

The key feature of an incremental encoder is that it shows changes in angle, not the exact position. That is, when an incremental encoder is turned on, it doesn’t know its starting position. It needs a reference point to start measuring from before it can tell you the angle.

Principle: An incremental encoder is a device that measures changes in motion and direction. Incremental rotary encoders generate A/B digital output signals based on a specific number of pulses per rotation. In this way, the angular motion of a shaft is converted into a code (encoded) to determine its velocity or relative position.

Advantages:

- Simple design and lower cost compared to absolute encoders.

- High resolution available (precise measurement of small movements).

- Compact and easy to integrate into systems.

- Widely available and used in many industries.

- Ideal for measuring speed and relative position.

Disadvantages:

- Only provide relative position – need a reference point for absolute position.

- Lose position data after power failure (must re-home/reset).

- Errors can accumulate if pulses are missed (due to noise or vibration).

- Not suitable for critical applications requiring exact position memory.

Applications:

- Packaging Industry: Controlling cutting, filling, and labelling speeds.

- Textile Machinery: Synchronisation of rollers.

- Industrial Motors & Drives: Feedback for motor speed regulation.

- Printers & Scanners: Tracking print head or roller movement.

- CNC Machines & Robotics: For monitoring motor speed and relative shaft position.

Absolute Rotary Encoder

Absolute rotary encoders can directly read the exact position of a rotating part without any need to calculate the position from a starting point or number of rotations.

An absolute encoder has multiple code rings with various binary weightings which provide a data word representing the absolute position of the encoder within one revolution. This type of encoder is often referred to as a parallel absolute encoder. They can accurately provide the position of a rotating shaft relative to its initial state, acting as precise angle sensors. This means that even after a system restart, the exact position is retained, preventing any drift or loss of position data.

Principle: Absolute encoders work on the principle of a coded disc and sensors. The disc has concentric tracks, each representing binary values. As the shaft rotates, sensors read these track patterns. Each position generates a unique digital code (binary/Gray code). This code directly corresponds to the exact shaft angle.

Advantages:

- Retain position information even after power loss.

- Provide unique position values for each shaft angle – no need for homing.

- Immune to cumulative error since every position is unique.

- Can provide both position and speed data.

- More reliable in critical and safety-related applications (e.g., aerospace, robotics).

Disadvantages:

- More complex design and circuitry.

- More expensive than incremental encoders.

- Bulkier in some models compared to incremental ones.

- Slower response time in some cases (though modern versions are fast).

Applications:

- Aerospace & Defense: Navigation, control surfaces, radar positioning.

- Robotics: Arm/joint position tracking with high precision.

- Medical Equipment: MRI machines, robotic surgery, patient tables.

- Elevators & Cranes: Position monitoring for safety and accuracy.

- Renewable Energy: Wind turbine blade positioning and yaw control.

- Automated Guided Vehicles (AGVs): For precise navigation and positioning.

Based on different sensing technology

1. Magnetic Rotary Encoders:

Magnetic encoders are a type of rotary encoder that use sensors to identify changes in magnetic fields from a rotating magnetized wheel or ring.

Principle: As the wheel or ring spins past the magnetic sensor, the magnetic poles create a response in the sensor depending on the strength of the magnetic field. This response is processed by an electrical circuit and then sent as a digital signal to the device controlling the system.

Advantages:

- Robust, resistant to dust, dirt, and oil.

- Work well in harsh industrial environments.

- Cost-effective compared to absolute optical encoders.

- Compact and reliable for long-term use.

Disadvantages:

- Lower resolution and accuracy compared to optical encoders.

- Can be affected by strong external magnetic fields.

- Not suitable for ultra-precise applications.

Applications:

- Automotive systems (steering, throttle position).

- Robotics (wheel and joint sensing).

- Industrial machinery operating in harsh conditions.

- Renewable energy (wind turbine pitch control).

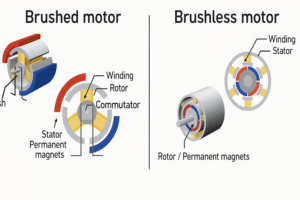

2. Mechanical Rotary Encoders:

Mechanical rotary encoders (conductive encoders) use concentric copper rings and contact brushes to create a positionally encoded conduction that can be read by an electronic circuit.

Principle: Mechanical rotary encoders consist of a rotating disc, a fixed disc, and a reader. They’re used to detect the position and movement of rotating objects. The rotating disc has slots, and the fixed disk positioned below it has matching slots.

The reader is mounted above or below the rotating disc and it detects changes in the slots. When the disc rotates, the reader senses the slots and generate corresponding pulse signals. The angle and position of the rotating part can be determined by analyzing the quantity and sequence of pulse signals and the accuracy and resolution of encoder depend on the density and arrangement of the slots on the disc.

Advantages:

- Very simple and inexpensive.

- Easy to implement in basic systems.

- Provide tactile feedback (useful for knobs in electronics).

Disadvantages:

- Not suitable for high-speed or precision applications.

- Wear and tear due to physical contact so, shorter lifespan.

- Limited resolution and accuracy.

Applications:

- Consumer electronics (volume knobs, washing machines, microwaves).

- Consumer electronics, appliances

- Low-cost control systems and small household appliances.

3. Optical Rotary Encoders:

An optical encoder is an electro-mechanical motion sensor and feedback device consisting of an LED light source, a photodetector, and a disc with slot-like apertures.

Principle: A light pulse is created when an opening in the rotating disc allows light from the LED to pass through and strike a paired photodetector. The photodetector is typically an array of photodiodes arranged so they provide two signals which are out of phase by 90 electrical degrees.

The light pulses alternate between on/off as the disc turns with the rotation of the shaft, alternately blocking or allowing light to pass through. The photosensor is connected to an electronic circuit which translates the light pulses into a digital square waveform (high and low signals).

Advantages:

- Can provide incremental or absolute outputs.

- Fast response, suitable for high-speed applications.

- Very high resolution and accuracy.

- Reliable in clean environments.

Disadvantages:

- Sensitive to dust, dirt, and oil (performance can degrade).

- Require careful alignment and clean operating conditions.

- More expensive than mechanical or magnetic encoders.

Applications:

- Medical equipment (MRI, robotic surgery).

- Semiconductor manufacturing.

- CNC machines and precision robotics.

- Aerospace navigation and defense systems.

4. Capacitive Rotary Encoders:

Capacitive rotary encoders are sensors that detect rotational positions by measuring changes in capacitance.

Principle: They typically consist of a fixed capacitance array, a rotating capacitance disc, and reading circuits. The fixed capacitance array is a group of capacitances, attached on stationary part, and the rotating disc is a capacitor mounted on the rotating component.

Its capacitance changes with rotation. As the rotating capacitance disc turns, the capacitance value between the fixed capacitance array changes with the rotation position. The reading circuit measures the changes in capacitance value to determine the angle or position information of the rotating component.

Advantages:

- Resistant to dust, moisture, and vibration.

- Good balance of accuracy and durability.

- Lower power consumption compared to optical encoders.

- Can be miniaturised for compact designs.

Disadvantages:

- Moderate resolution (not as high as optical).

- More expensive than mechanical encoders.

- Performance may vary with temperature/humidity changes.

Applications:

- Aerospace and defence (due to resistance to vibration).

- Portable devices requiring low-power encoders.

- Robotics with medium-precision requirements.

- Industrial automation in harsh environments.