INTRODUCTION

A DC motor, in essence, converts direct current (DC) into rotational mechanical energy a process rooted in fundamental principles of electromagnetism. When a conductor carrying current sits within a magnetic field, it experiences a force that induces motion, this is not only a foundational law of physics, but the basic mechanism underpinning all DC motor operation.

DC motors are ubiquitous due to their straightforward design and ease of control. Whether one examines common household devices such as fans, toys, or kitchen mixers or inspects more sophisticated systems like electric vehicles, factory automation equipment, or robotic platforms, DC motors are a prevalent choice.

Their practicality is particularly notable in contexts requiring both high starting torque and precise speed regulation. This ability to fine-tune performance metrics enables DC motors to play a critical role across an impressive array of technological and industrial applications.

Common Applications

DC motors are integrated into numerous products, such as:

- Toys

- Hairdryers

- Fans

- Electric vehicles

- Drones

- Robotic systems

How a DC Motor Works

The core functionality of a DC motor relies on the following:

- Magnetic fields

- Current-carrying wires

- Interaction between magnetism and electrical current to generate force and rotation

When direct current flows through the motor’s wiring, magnetic fields are produced. These fields interact with components inside the motor to create consistent mechanical motion.

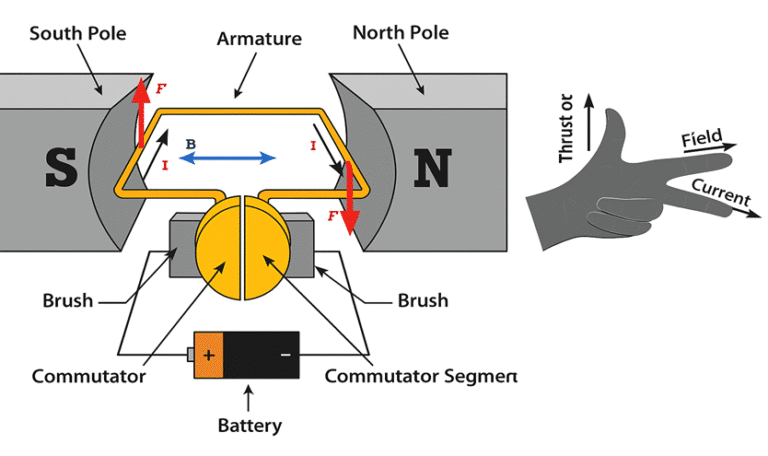

Why Do DC Motors Spin? Fleming’s Left-Hand Principle Explained

Fleming’s Left-Hand Rule serves as a straightforward framework for understanding motor mechanics, especially for professionals dealing with electromechanical systems.

Fleming’s Left-Hand Rule: A Practical Guide

- Hand Positioning:

- Extend your left hand, with thumb, index finger, and middle finger all at right angles to each other.

- Finger Representation:

- Index Finger – Indicates the direction of the magnetic field.

- Middle Finger – Indicates the direction of the current.

- Thumb – Indicates the direction of the resulting force or motion.

Application within the Motor

- Armature Winding:

- The armature consists of coiled wire through which current flows.

- Magnetic Field:

- Generated either by electromagnetic windings or permanent magnets.

- Interaction and Force Generation:

- When current-carrying conductors within the armature interact with the magnetic field, a force is exerted.

- This interaction produces continuous torque.

- The generated torque results in sustained rotation of the motor shaft.

Key Takeaways

- The correct orientation of magnetic field and current flow, as indicated by Fleming’s Left-Hand Rule, is essential for motor operation.

- Continuous interaction between the current in the armature and the magnetic field ensures efficient and reliable motor rotation.

- Mastery of this concept is fundamental for anyone involved with motor-driven systems.

Classification of DC Motors

DC motors are among the most widely used machines in industries, robotics, home appliances, and electric vehicles. They convert direct current (DC) electrical energy into mechanical rotation.

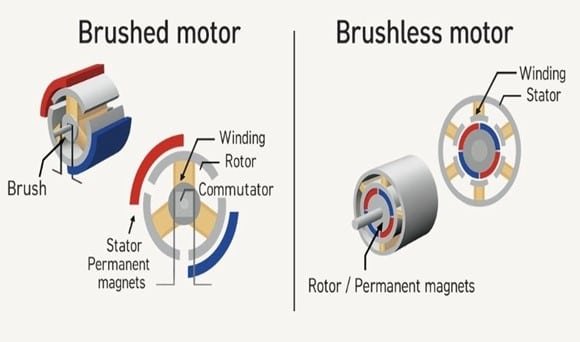

There are many kinds of motors, but two popular types are:

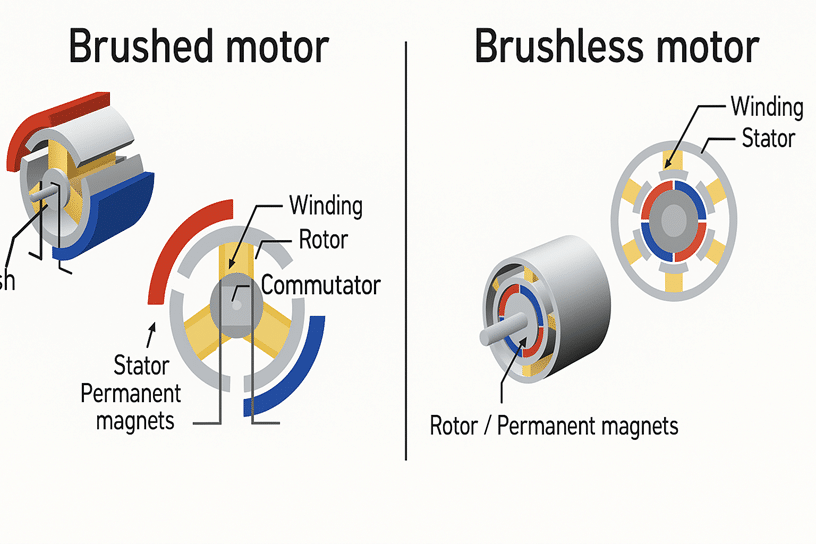

- Brushed DC Motor

- Brushless DC Motor (BLDC)

Generation of Magnetic Fields in Electric Motors (Field Excitation)

A functioning electric motor is fundamentally dependent on the presence of a magnetic field, enabling rotational motion. The method of generating this field varies by motor type:

1. Brushed DC Motor:

- Magnetic fields are produced either by permanent magnets (comparable to those used on household refrigerators) or by electromagnets created from coils of wire carrying electrical current.

- The interaction between this magnetic field and the armature (the rotating component) provides the torque necessary for rotation.

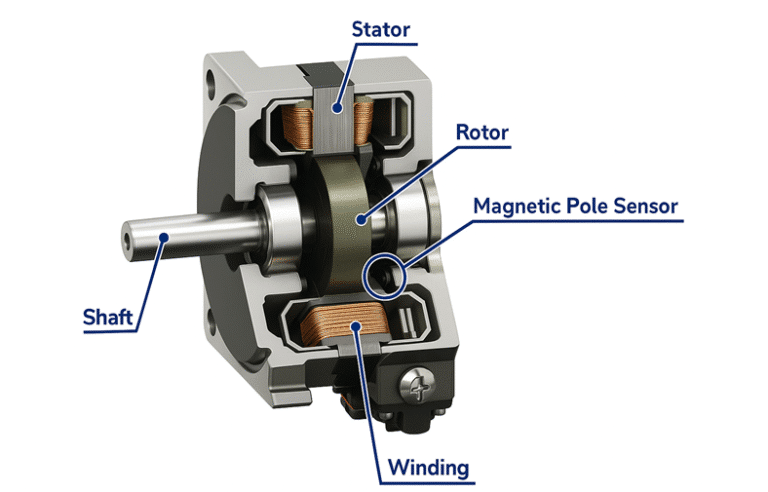

2. Brushless DC Motor (BLDC):

- The rotor (the part that rotates) is equipped with permanent magnets.

- The stator (the stationary part) consists of coils of wire through which current is passed.

- An electronic control circuit precisely switches the current in the stator coils, creating a rotating magnetic field that ensures consistent and efficient rotor movement.

Current Switching Mechanisms (Commutation)

Effective motor operation relies on altering the direction of current at specific points in the rotation cycle—a process termed commutation. The approach differs substantially between brushed and brushless designs:

1. Brushed DC Motor:

- Utilizes mechanical brushes (typically carbon blocks) in contact with a segmented copper commutator.

- As the motor rotates, the brushes automatically reverse current direction in the armature windings.

- This method is straightforward and cost-effective, but introduces mechanical wear, electrical noise, and sparking, limiting operational lifespan and efficiency.

2. Brushless DC Motor (BLDC):

- Eliminates the need for brushes by employing an electronic controller to switch the current.

- This controller may use sensors or rely on precise circuitry to manage timing.

- The absence of brushes and commutator allows BLDC motors to operate with reduced noise, minimal wear, and greater longevity compared to brushed alternatives.

Brushed DC Motors

Advantages

- Straightforward design: Brushed DC motors are constructed simply, making them easy to comprehend and operate.

- Cost-effective: These motors are inexpensive to manufacture, which makes them accessible for a range of applications.

- No fancy controller required: They function without the need for advanced electronic controllers.

- Suitable for basic use: Commonly found in small toys, household tools, and basic machinery.

Disadvantages

- Brush wear: The brushes deteriorate over time, necessitating periodic replacement.

- Operational issues: The design can generate electrical sparks and mechanical noise during operation.

- Lower efficiency: These motors tend to waste more energy, usually dissipating it as heat.

- Limited speed range: Brushed DC motors do not perform well at very high rotational speeds.

Brushless DC Motors (BLDC)

Advantages

- Minimal maintenance: The absence of brushes leads to fewer parts that degrade, reducing maintenance demands.

- High efficiency: BLDC motors are notably energy efficient, reducing power loss and heat generation.

- Quiet operation: Their design minimizes both noise and electrical sparking.

- High-speed capability: They can reliably operate at higher speeds.

- Enhanced durability: BLDC motors generally have a longer operational lifespan compared to brushed variants.

Disadvantages

- Higher initial cost: These motors tend to be more expensive due to more complex construction.

- Need for a controller: BLDC motors require an electronic controller to function, adding cost and design complexity.

- More challenging to repair: Their advanced design makes at-home repairs more difficult.

Brushed vs Brushless: Comparison

1. Magnetic Field

- Brushed DC Motor: Utilizes magnets or coils to produce the magnetic field.

- Brushless DC Motor: The stator houses the coils, while magnets are used in the rotor.

2. Commutation

- Brushed DC Motor: Relies on physical brushes and a commutator to handle the commutation process.

- Brushless DC Motor: Employs an electronic controller for commutation, eliminating the need for brushes.

3. Maintenance

- Brushed DC Motor: Requires regular maintenance because the brushes wear out over time.

- Brushless DC Motor: Demands almost no maintenance due to the absence of brushes.

4. Efficiency

- Brushed DC Motor: Generally, exhibits lower efficiency compared to brushless designs.

- Brushless DC Motor: Offers higher efficiency, making it suitable for energy-conscious applications.

5. Lifespan

- Brushed DC Motor: Typically has a shorter operational lifespan as a result of mechanical wear.

- Brushless DC Motor: Known for its longevity, thanks to reduced mechanical contact.

6. Cost

- Brushed DC Motor: More affordable, making it accessible for basic applications.

- Brushless DC Motor: Higher initial costs are justified by performance and durability.

7. Applications

- Brushed DC Motor: Commonly found in toys, car starters, and simple electronics.

- Brushless DC Motor: Preferred for advanced uses such as drones, electric vehicles, robots, and computers.

Conclusion

Brushed DC motors provide simplicity and affordability, suitable for less demanding applications, but face challenges with maintenance, noise, and efficiency. Brushless DC motors deliver improved efficiency, longevity, and quiet operation, though at the cost of higher complexity and price. Selection depends on application requirements, budget constraints, and maintenance capabilities.